Custom Printings - One Stop Plastic Bucket Supplier

Screen Printing

Screen Printing is a standard process for printing on plastic buckets, transferring ink through small holes in the screen to form patterns and text. This process suits simple patterns and rough textures with good durability and color saturation. Our screen printing technology ensures precise, long-lasting, and durable graphics that won’t fade or peel.

Thermal Transfer Printing

Thermal Transfer Printing is a high-temperature printing process that transfers patterns and text to the surface of a plastic bucket. The ink on the Thermal Transfer Printing film is transferred to the plastic bucket by hot pressing and high temperature. Thermal Transfer Printing allows more intricate patterns and details to be printed with brighter, fuller colors. The process is abrasion- and weather-resistant, ensuring long-lasting, transparent, chemical-resistant designs and resistant to the external environment.

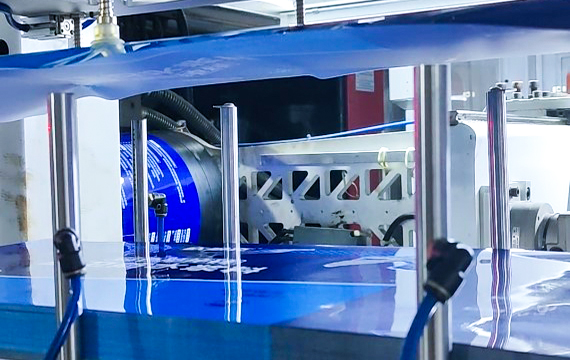

In-Mould Labelling

In-Mould Labelling is a printing process in which the label is placed inside a plastic bucket. The title is wrapped in a transparent film and then heated with a plastic bucket to adhere to the bucket’s inner surface. This process produces beautiful patterns and color effects while protecting the label from the external environment and chemicals. In-mould labels are durable, waterproof, and scratch-resistant, ensuring long-lasting, transparent, and fade-resistant branding.

Case Sharing

- Screen Printing

- Thermal transfer printing

- In-Mould Labelling